our approach aimed at maximizing productivity & efficiency.

Managing Director

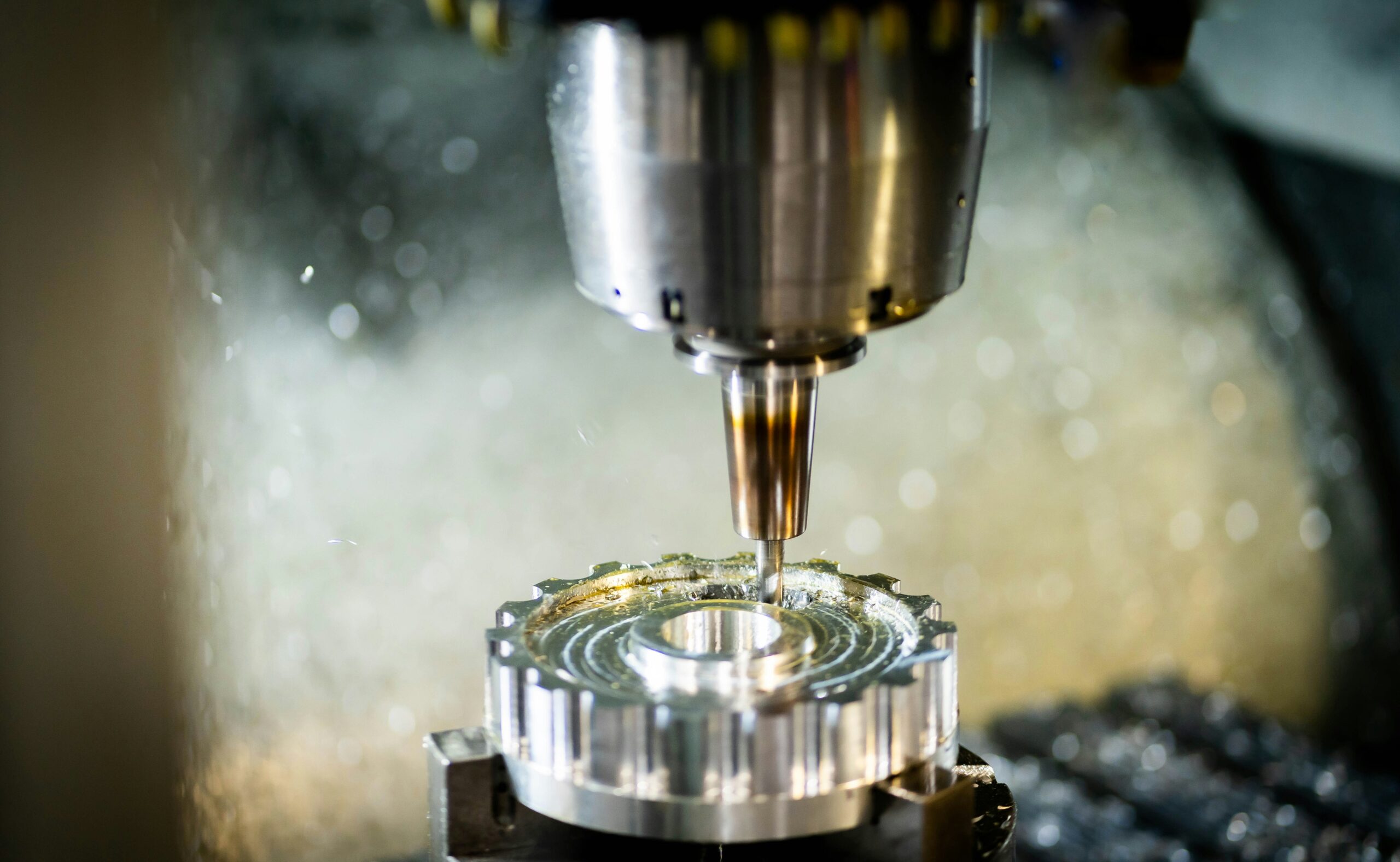

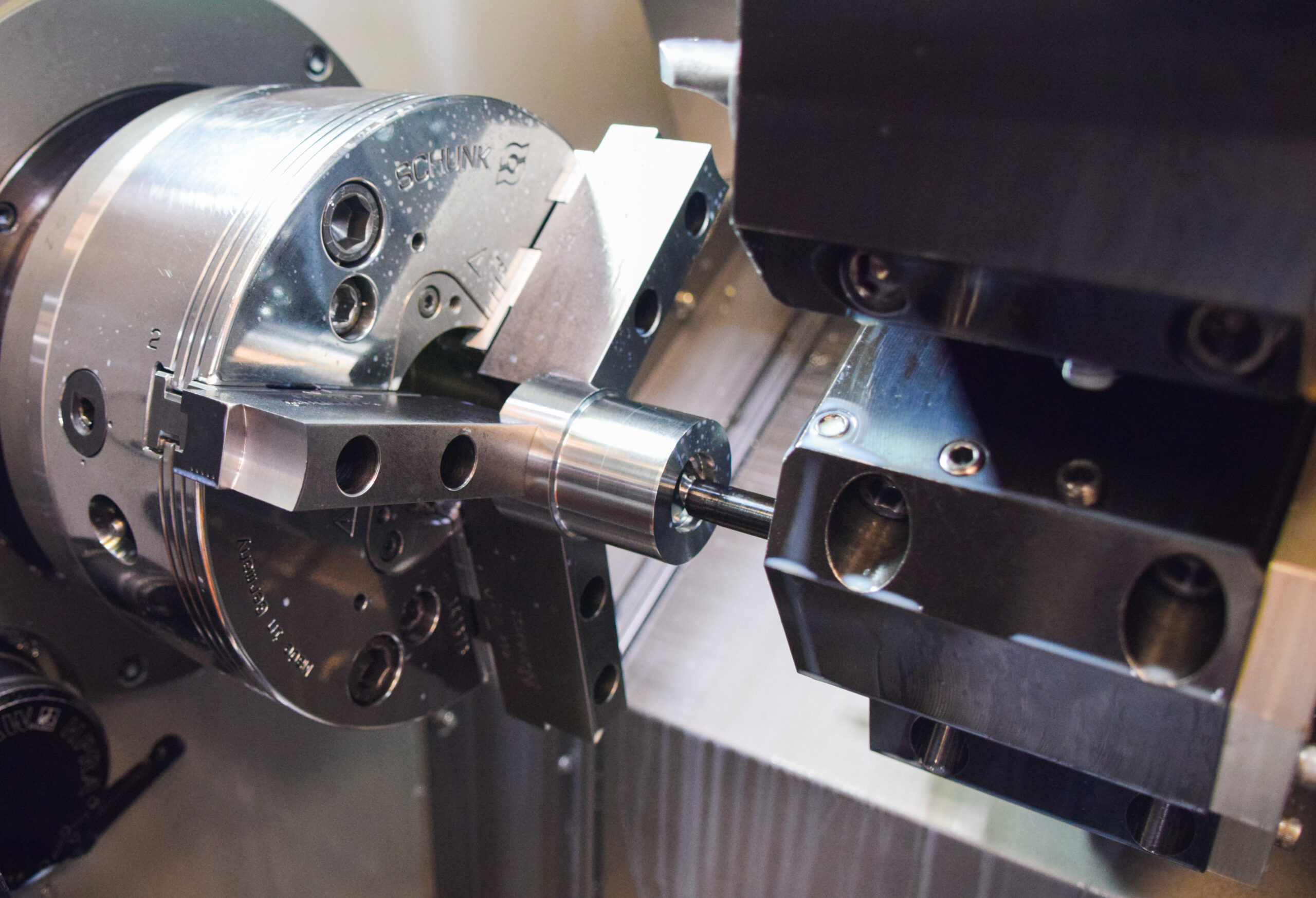

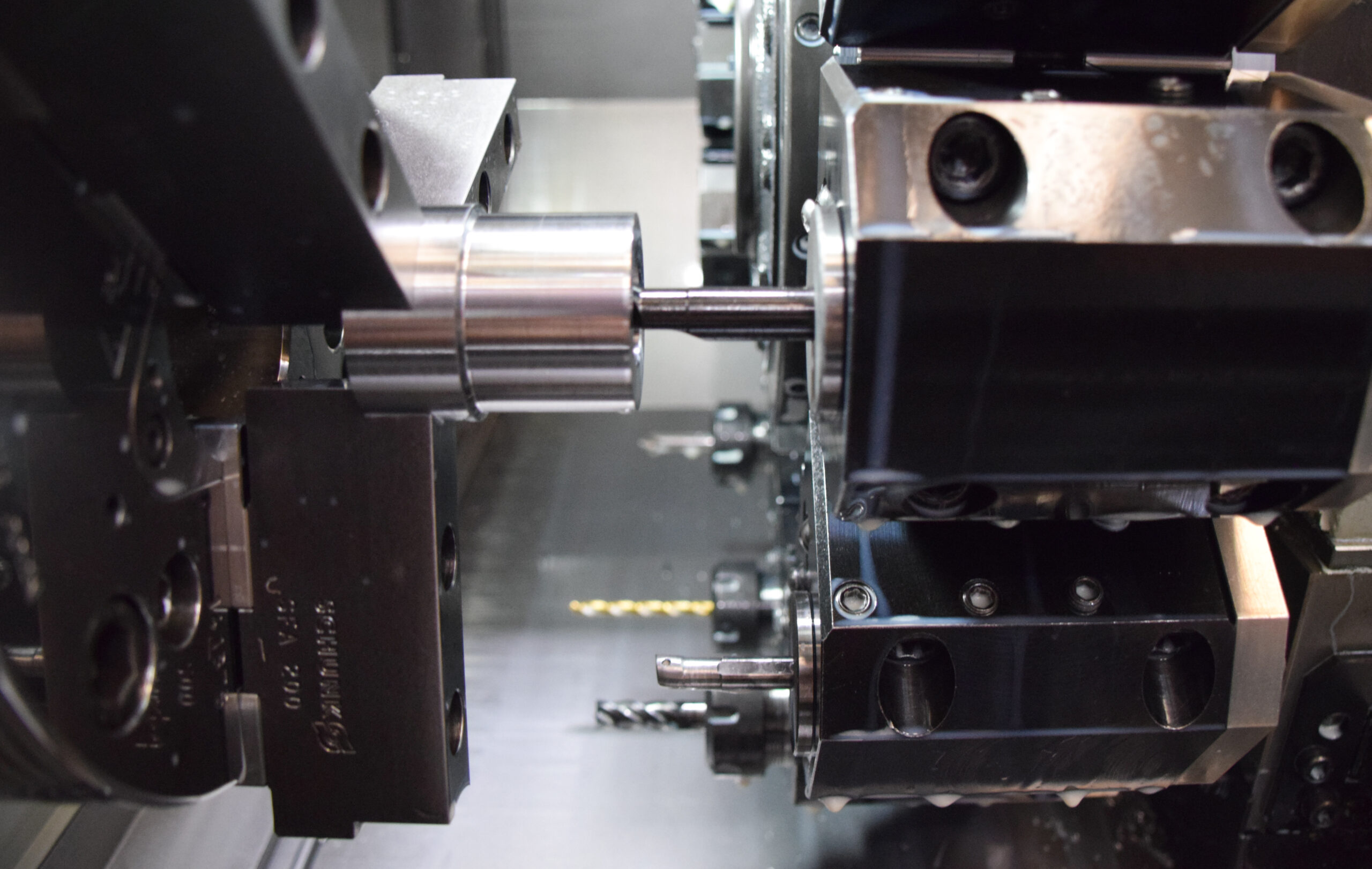

Equipped for Precision

At Kristek Precision, inspection is more than a final check — it’s a core part of our process control. Our inspection team is equipped with a full suite of calibrated tools to verify both standard and tight-tolerance features, including:

All equipment is registered and regularly calibrated to ensure measurement confidence.

Process-Led Inspection Coverage

Our inspection process is defined by risk, complexity, and customer requirements. We typically:

- Inspect critical features, process-specific features, and customer-defined tolerances

- Perform 100% inspection on NPI (New Product Introduction) parts

- Use Route Cards to record who inspected what, on which machine, using which equipment — including verification

First-Offs are approved by our Quality Department or trained, competent personnel with appropriate sign-off authority.

Reporting & Traceability

We provide inspection documentation that meets the needs of production-grade buyers, including:

- AS9102 First Article Inspection Reports (FAIRs) where required

- Stamped Route Cards tracking inspection activity and accountability

- Customer-specific forms or formats (on request)

All inspection data is retained in line with our 10+ year digital record policy, forming part of our overall traceability system.

Tolerances & Capability

While general tolerances are typically ±0.15mm, we frequently machine and inspect parts to:

- ±0.015mm, ±0.01mm, and down to ±0.005mm where required

- Geometric tolerances and feature callouts per customer drawings

Whether the job involves production runs or NPI parts with tight dimensional control, our inspection processes are built to verify compliance with confidence — every time.

Inspection related FAQ’s

We routinely machine to tight tolerances based on customer specifications and part complexity. Typical tolerances range from ±0.005mm to ±0.015mm, depending on the material and geometry. Tolerance capabilities will be confirmed during the technical review, before a quote is produced.

Our core focus is batch work, and production. Our systems and processes are developed around being able to supply consistent and reliable parts with high-quality standards.

That being said, some customers need a verification batch or initial design before they go into production, we can help with this too.

Yes. Kristek Precision is fully AS9100 Certified, which means our quality management system meets the aerospace and defence industry’s standards. We follow rigorous inspection and documentation protocols on every job.

You can view our certification here.

Yes – by default all orders receive a C of C, included. However, we can also provide full First Article Inspection (FAI) reports and dimensional inspection reports, if required. All inspections are carried out in-house using calibrated CMM and precision tools. For FAI we use the AS9102 standard but can use customer specific reports too.

We primarily serve the automotive testing, aerospace, defence, power generation, as well as various OEMs. Our AS9100 certification makes us a trusted partner for products with strict quality and traceability requirements.